Two bi-directional slip modules allow loads in either direction and self centralise the tool on setting. On retrieval the slips are positively retracted from the tubing/casing wall to their running position.

The gauge hanger can be run on slickline or electric cable and is set using standard-setting tools. Retrieval is with a JDC pulling tool for simplicity.

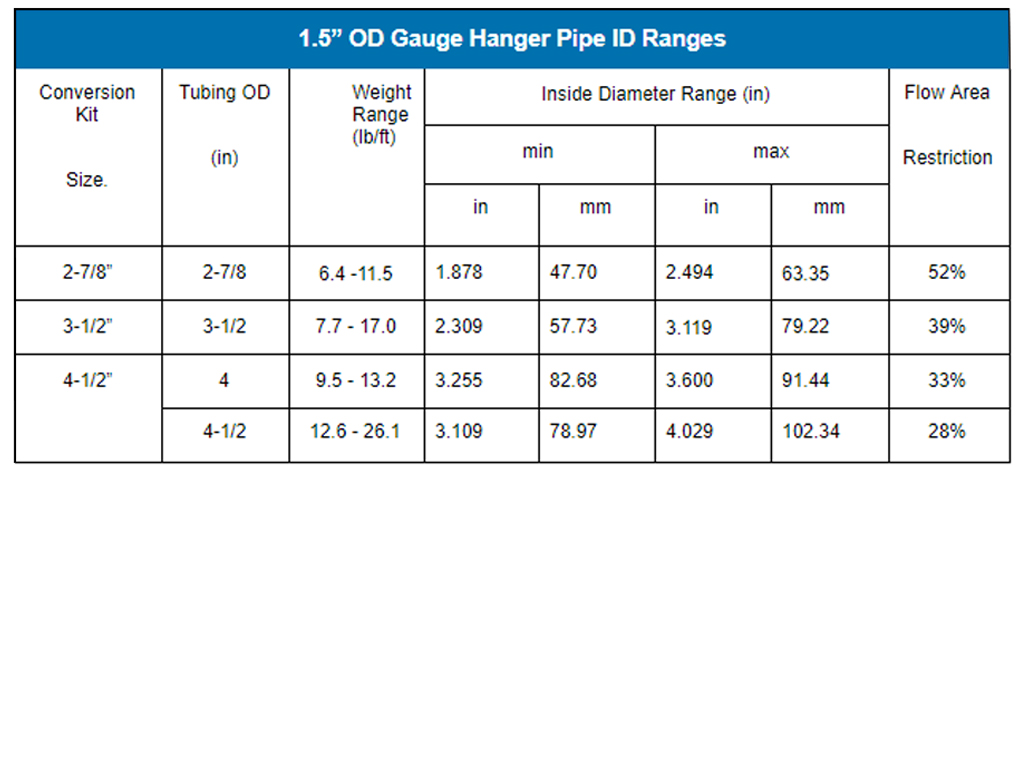

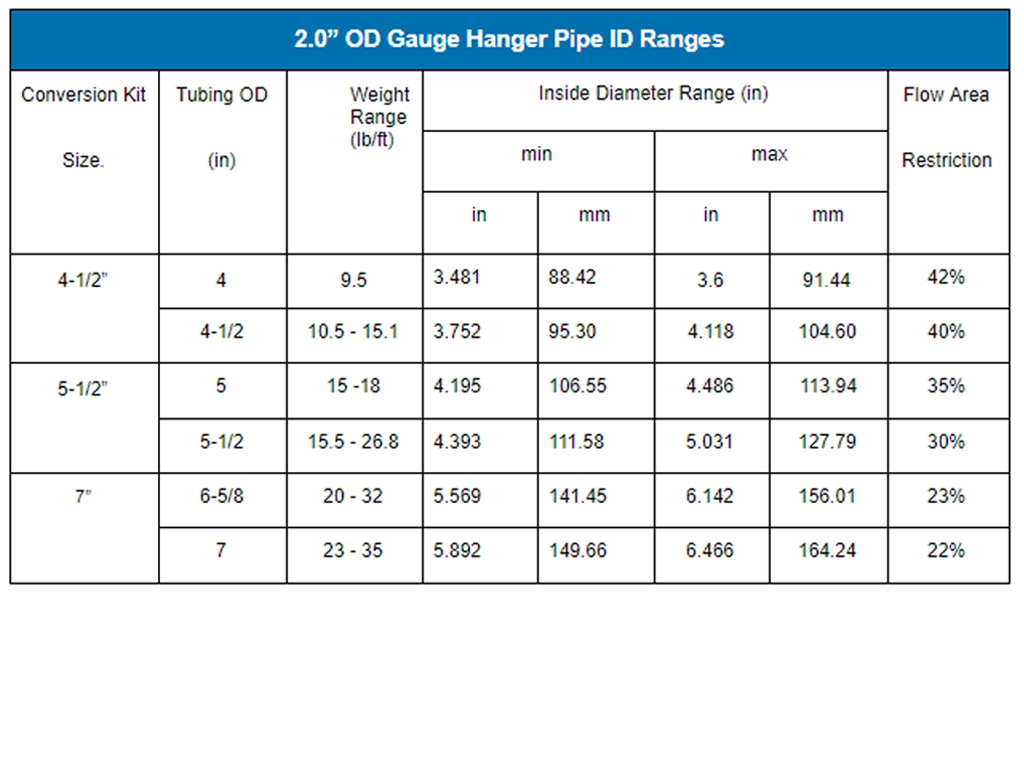

The gauge hanger comes in three chassis sizes:

- 1.5”, 2.0”, and 2.88” OD`s. Conversion kits enable the gauge hanger to be set in a range of tubing sizes from 2-7/8” through to 7”.