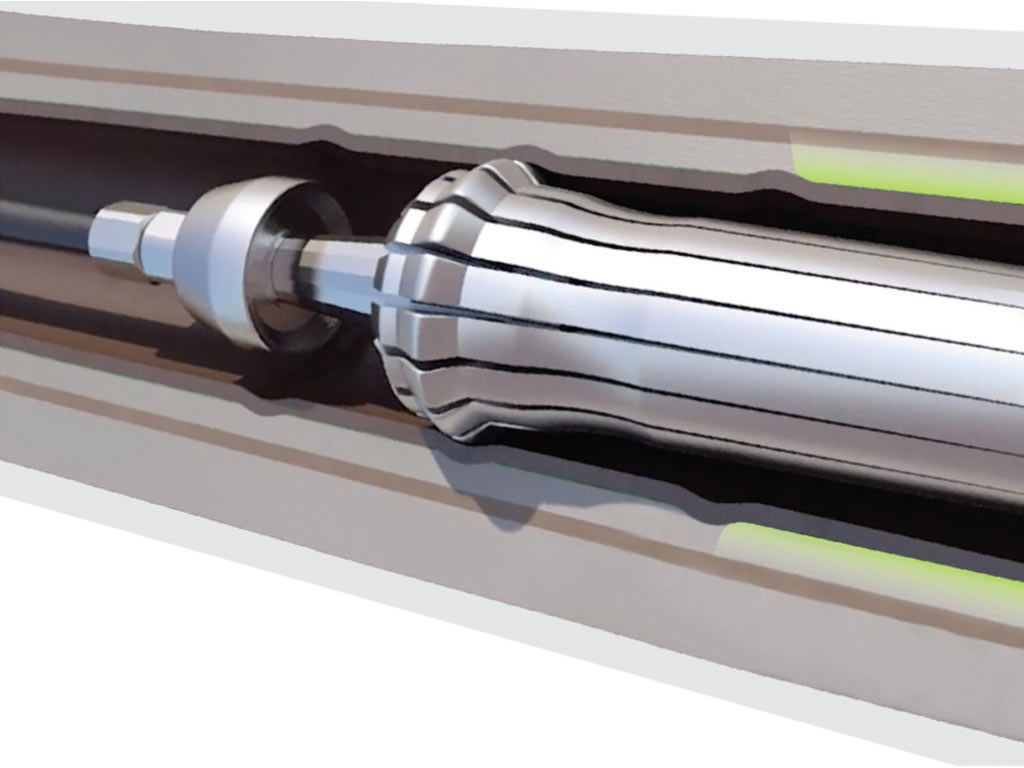

(Image Source: Renegade Services)

LOCAL EXPANDER

LOCAL EXPANDER

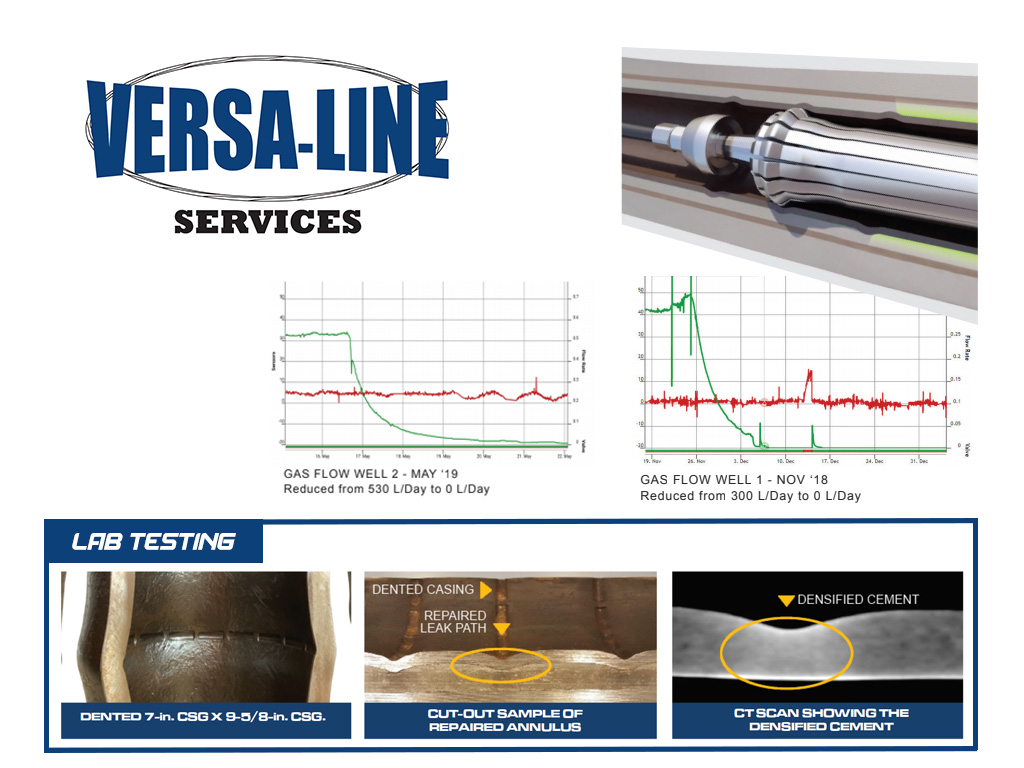

Versa-line is the preferred vendor for Renegade Services Local Expander. Our strategic relationship allows Renegade Services to bring this necessary technology to the Canadian Market.

As is normal for any industry, new and improved technologies are introduced that completely transform how work is done. When traditional cement remediation techniques fail to meet modern requirements, what new technology can industry experts expect to surface?

During well construction, the formation of micro-annulus can be dangerous. Through improper hole cleaning or uneven displacement rates, micro-annulus can form and offer dangerous gases a path to the surface. For many years, there were no promising alternatives to the traditional permanent-fixture casing expansion technique, until now.

The new tool that is quickly changing the well construction process is the Local Expander. It offers a new and cost-effective approach to solving problems like micro-annulus and sustained casing pressure. A Local Expander is a tool deployed by electric wireline that stops the unintended gas flow with its telescoping cone by extending radial knuckles to mechanically closed the micro-annulus.

Features

- E-line deployable, i.e. low cost

- No ID reduction after repair

- Fully re-usable, no sacrificial parts

- Multiple dents can be set per run

- No perforations are required

- The annulus is not opened

- Fully controlled expansion

(Image Source: Renegade Services)

These hardened knuckles have a variable displacement distance that allows for flexibility in correcting the annulus along the wellbore. Local Expander allows for quick completion of the crimping cycle and easy movement to the next location. Multiple crimps should be inserted at target depth intervals to fully eradicate all micro-annulus and backside gas flow problems.

You may be wondering how this new technology works. It’s surprisingly simple.

The metal fingers at the tip of the nozzle are mechanically separated by the actuated cone, causing them to forcefully expand into the existing cement and apply a squeezing pressure on the casing locally. This pressure on the cement causes the casing to swell, extending into the micro-annulus and effectively inserting a crimp that closes any gaps or small channels.

While a traditional squeeze technique creates these same crimps, the Local Expander uses an electric line and is a one-run tool, which achieves the same result at a fraction of the cost and effort.

This tool also significantly eliminates the safety concerns for workover operations. Operating crews can work from the surface, in much safer conditions and without having to deal with escaping gas.

Local Expander also increases the safety of wells marked for Plug and Abandon. Due to a lack of economic pressures at the end of a well’s lifecycle, it’s unfortunately too common to see wells abandoned. There is a risk to the public when pressure builds up, which is why Local Expander is the technology of choice for scheduled Plug and Abandons. It is a cost-effective means to safely Plug and Abandon a well to ensure that no gases will escape and pose any risk to the public.

Local Expander also has great potentials in other areas of the well construction process. A promising new application for the Local Expander is in the whipstock stage. It takes lots of time and money to conduct whipstock operations properly, which has led to some crews speeding up the process too quickly and not giving cement enough time to dry or bonds to form between the formation wall.